Defending Devices: A Guide to Preventing Static Electrical Damage

Table of Contents

The Ground Connection: Protecting Your Electronics from Static Damage

Static electricity can pose a significant threat to electronic devices, causing irreparable damage and costly repairs. Understanding how static electricity works and the common sources of static discharge is crucial in protecting your electronics. Grounding plays a vital role in preventing static damage, and there are various methods available to ensure a solid ground connection. In addition to grounding, using anti-static mats and wristbands, practicing proper handling and storage techniques, and avoiding static-prone environments can help safeguard your electronics. Educating employees about static electricity, implementing ESD control measures, and conducting regular maintenance and inspections are essential in preventing static damage incidents. By learning from real-life case studies, we can gain valuable insights into the costly consequences of static damage and apply best practices to protect our electronics.

Key Takeaways

- Understanding static electricity is crucial in protecting electronics from damage.

- Grounding is essential for preventing static discharge and protecting electronics.

- Using anti-static mats and wristbands can help dissipate static electricity.

- Proper handling and storage techniques are important in preventing static damage.

- Educating employees, implementing ESD control measures, and conducting regular maintenance are key in preventing static damage incidents.

Understanding Static Electricity

What is static electricity?

Static electricity is the accumulation of electric charge on the surface of an object. It occurs when there is an imbalance of positive and negative charges. This imbalance can be caused by friction, contact, or separation of materials. Electric charge refers to the property of matter that causes it to experience a force when placed in an electromagnetic field. Static electricity is different from current electricity, which is the flow of electric charge in a conductor.

- Static electricity is a common phenomenon that we encounter in our daily lives.

- It can be generated by activities such as walking on a carpet, rubbing objects together, or even by the movement of air.

- Static electricity can build up on objects and discharge when there is a path for the electric charge to flow.

- The discharge of static electricity can cause damage to sensitive electronic components and devices.

Tip: To prevent static electricity buildup, it is important to use anti-static mats and wristbands when handling electronics.

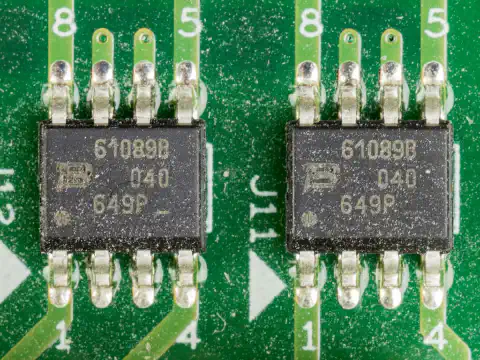

How does static electricity damage electronics?

Static electricity can cause significant damage to electronic devices. When an electronic component comes into contact with a static charge, it can experience a sudden discharge of energy, leading to a phenomenon known as electrostatic discharge (ESD). ESD can result in the following consequences:

- Component Failure: The high voltage from the static charge can cause the breakdown of delicate electronic components, leading to their malfunction or complete failure.

- Data Loss: ESD can corrupt or erase data stored in electronic devices, resulting in the loss of important information.

- Reduced Lifespan: Continuous exposure to static electricity can gradually degrade the performance and reliability of electronic devices, reducing their lifespan.

To prevent these damaging effects, it is crucial to implement proper ESD control measures and educate individuals on the risks and precautions associated with static electricity.

Common sources of static electricity

Static electricity can be generated from a variety of sources. Understanding these sources is crucial in preventing damage to your electronics:

Friction: When two materials rub against each other, electrons can be transferred, resulting in static electricity. Common examples include walking on carpets, rubbing balloons on hair, or sliding materials across each other.

Induction: Static electricity can also be induced when a charged object comes close to an uncharged object. This can occur when you touch a doorknob after walking on a carpet, or when you bring a charged object near electronic components.

Conduction: Direct contact with a charged object can transfer static electricity. This can happen when you touch a metal surface that is charged, such as a metal doorknob or a metal computer case.

It is important to be aware of these common sources of static electricity and take necessary precautions to protect your electronics.

The Importance of Grounding

What is grounding?

Grounding is the process of connecting an electrical device or system to the ground, which serves as a reference point for electrical potential. It provides a path for the discharge of excess electrical energy, including static electricity, to prevent damage to the device or system.

Grounding helps to maintain the electrical balance and stability of the device or system, reducing the risk of electrical shock and fire hazards. It also helps to protect against electromagnetic interference (EMI) and ensures proper functioning of sensitive electronic components.

Importance of grounding:

- Safety: Grounding helps to prevent electrical shocks and fires by providing a path for excess electrical energy to dissipate safely.

- Protection: It protects electronic devices from damage caused by static electricity and voltage surges.

- Reliability: Grounding ensures the proper functioning of electronic components by maintaining electrical stability and reducing EMI.

Types of grounding methods:

- Earthing: Connecting the device or system directly to the ground using a conductive wire or rod.

- Equipment grounding: Connecting the metal parts of the device or system to the ground to prevent electrical shock.

- System grounding: Connecting the neutral point of the electrical system to the ground to stabilize voltage levels and protect against electrical faults.

Why is grounding important for electronics?

Grounding is a crucial aspect of protecting electronics from static damage. Static electricity can build up on surfaces and objects, creating a potential difference that can discharge and damage sensitive electronic components. Without proper grounding, this static charge can accumulate on electronic devices, leading to costly malfunctions or even permanent damage.

To ensure the safety and functionality of electronics, grounding provides a path for the static charge to dissipate harmlessly into the ground. This prevents the charge from building up and eliminates the risk of static discharge. By establishing a connection between the electronic device and the ground, grounding helps maintain a stable electrical environment.

To achieve effective grounding, there are various methods available:

- Earth grounding: This method involves connecting the electronic device to a conductive path that leads directly to the earth. It provides a low-resistance path for static charge dissipation.

- Equipment grounding: This method involves connecting the electronic device to a conductive path within the equipment itself. It ensures that any static charge buildup is safely redirected to the ground.

- Bonding: This method involves connecting all conductive parts of the electronic system together to create a common ground reference. It helps equalize potential differences and prevents static charge accumulation.

Implementing proper grounding techniques is essential for safeguarding electronics and minimizing the risk of static damage.

Types of grounding methods

There are several types of grounding methods that can be used to protect electronics from static damage:

Earthing: This method involves connecting the electronic device to the Earth’s surface through a conductive material, such as a metal rod or a grounding wire. It allows any static charge to be safely discharged into the ground.

Grounding straps: These are conductive straps that are worn around the wrist or ankle and are connected to a grounding point. They help to dissipate any static charge that may build up on the body.

Grounding mats: These mats are made of conductive material and are placed on the work surface. They provide a path for static charge to flow into the ground, preventing it from accumulating on the surface.

Grounding plugs: These plugs are inserted into electrical outlets and provide a direct connection to the ground. They can be used to ground electronic devices that do not have a built-in grounding feature.

Grounding cages: Also known as Faraday cages, these are enclosures made of conductive material that completely surround the electronic device. They prevent external static charges from reaching the device.

Grounding wristbands: Similar to grounding straps, these wristbands are worn around the wrist and are connected to a grounding point. They help to dissipate any static charge that may build up on the body.

Protecting Your Electronics

Using anti-static mats and wristbands

Anti-static mats and wristbands are essential tools for protecting your electronics from static damage.

- Anti-static mats provide a conductive surface that helps to dissipate static electricity.

- Placing your electronics on an anti-static mat during assembly or repair can prevent static discharge.

- Anti-static wristbands are worn by technicians to ground themselves and prevent the buildup of static electricity.

- These wristbands are connected to a grounding point, such as a grounded workbench or a grounding strap.

Using anti-static mats and wristbands is a simple yet effective way to minimize the risk of static damage to your electronics.

Tip: Make sure to regularly inspect and replace worn-out mats and wristbands to maintain their effectiveness.

Proper handling and storage of electronics

Proper handling and storage of electronics is crucial to prevent static damage. By following these best practices, you can minimize the risk of static electricity causing harm to your valuable electronic devices:

- Always handle electronic components with anti-static gloves or wristbands to discharge any static electricity from your body.

- When storing electronics, use anti-static bags or containers to provide a protective barrier against static charges.

- Avoid placing electronic devices on surfaces that generate static electricity, such as carpets or plastic.

- Keep electronic devices away from sources of static electricity, such as strong magnetic fields or high-voltage equipment.

Remember, even a small static discharge can cause irreversible damage to sensitive electronic components. Taking the necessary precautions when handling and storing electronics is essential to ensure their longevity and functionality.

Avoiding static-prone environments

When it comes to protecting your electronics from static damage, it is crucial to be aware of environments that are prone to static electricity. Static-prone environments are areas where static electricity is more likely to occur, increasing the risk of damaging your electronics. Here are some important points to consider:

- Dry environments: Dry air can increase the buildup of static electricity. Avoid using electronics in areas with low humidity.

- Carpeted areas: Carpets can generate static electricity, especially when they are made of synthetic materials. Consider using anti-static mats in these areas.

- Workspaces with plastic surfaces: Plastic surfaces can generate static electricity. Use anti-static mats or grounding methods to minimize the risk.

Remember, being mindful of the environment in which you use and store your electronics can go a long way in preventing static damage.

Static Damage Prevention Tips

Educating employees about static electricity

Static electricity can cause significant damage to electronic devices if not properly understood and managed. It is important to educate employees about the potential risks and preventive measures associated with static electricity. By providing the necessary knowledge and training, employees can play an active role in minimizing static damage incidents.

To effectively educate employees about static electricity, consider the following:

- Conduct regular training sessions to raise awareness about the basics of static electricity, including its causes and effects.

- Emphasize the importance of proper grounding techniques and the use of anti-static equipment.

- Provide practical demonstrations to illustrate the impact of static electricity on electronic devices.

- Encourage employees to ask questions and seek clarification to ensure a thorough understanding of the topic.

By investing in employee education, organizations can create a culture of awareness and responsibility when it comes to static electricity. This proactive approach can significantly reduce the risk of static damage incidents and protect valuable electronic equipment.

Implementing ESD control measures

Implementing effective ESD control measures is crucial in protecting your electronics from static damage. By following these measures, you can significantly reduce the risk of ESD-related incidents:

- Use ESD-safe packaging: Ensure that all electronic components are stored and transported in ESD-safe packaging materials, such as conductive bags or containers.

- Grounding personnel and workstations: Properly ground personnel and workstations to prevent the buildup of static charges. This can be achieved through the use of grounded floor mats, wrist straps, and footwear.

- Implement ESD-safe work practices: Train employees on proper ESD-safe work practices, such as avoiding the use of synthetic materials that generate static electricity and handling electronic components by their edges.

- Regular equipment maintenance: Conduct regular inspections and maintenance of ESD control equipment, including grounding connections, wrist straps, and grounding cords.

Remember, implementing these ESD control measures is essential to safeguard your electronics and prevent costly static damage incidents.

Regular maintenance and inspections

Regular maintenance and inspections are crucial for preventing static damage to your electronics. By implementing a proactive approach, you can identify and address potential issues before they cause harm. Here are some key practices to consider:

- Cleaning: Regularly clean electronic components and surfaces to remove dust and debris that can accumulate and create static charges.

- Visual inspections: Conduct visual inspections to check for any signs of damage or wear on cables, connectors, and grounding systems.

- Testing: Perform regular testing of grounding systems and equipment to ensure they are functioning properly.

- Documentation: Keep detailed records of maintenance activities, including dates, findings, and any corrective actions taken.

Remember, regular maintenance and inspections are essential for maintaining the integrity of your electronics and preventing costly static damage incidents.

Case Studies: Static Damage Incidents

Costly consequences of static damage

Static damage incidents can have significant financial implications for businesses. The cost of repairing or replacing damaged electronics can be substantial, especially for high-value equipment. In addition to the direct cost of the damaged items, there may also be indirect costs such as lost productivity, downtime, and potential data loss. It is crucial for businesses to understand the potential consequences of static damage and take proactive measures to prevent it.

- Implementing ESD control measures can help minimize the risk of static damage incidents.

- Regular maintenance and inspections of electronic equipment can identify and address any potential issues before they cause damage.

- Educating employees about the dangers of static electricity and proper handling procedures can significantly reduce the likelihood of accidents.

Remember, prevention is key when it comes to static damage. By implementing the right protective measures and promoting a culture of awareness, businesses can avoid the costly consequences associated with static damage incidents.

Real-life examples of static damage incidents

Static damage incidents can have costly consequences for electronics. Here are some real-life examples of static damage incidents:

A manufacturing company experienced a significant loss when a static discharge caused a power surge, damaging multiple computer systems and resulting in a loss of critical data.

In a retail store, a customer accidentally caused static damage to a display monitor by touching it without proper grounding. The monitor had to be replaced, resulting in additional expenses for the store.

An electronics repair technician unknowingly caused static damage to a laptop while replacing a component. The damage was not immediately apparent, but the laptop failed to function properly after a few days, requiring further repairs.

These examples highlight the importance of taking precautions to prevent static damage to electronics. By implementing proper grounding techniques and following best practices for handling and storing electronics, the risk of static damage can be significantly reduced.

Lessons learned and best practices

After analyzing various static damage incidents, several important lessons and best practices have emerged:

- Proper training and education about static electricity and its potential impact on electronics is crucial. Employees should be aware of the risks and understand how to handle electronics safely.

- Implementing an Electrostatic Discharge (ESD) control program is essential to minimize the risk of static damage. This program should include measures such as using anti-static mats and wristbands, implementing proper handling and storage procedures, and regularly inspecting equipment.

- Regular maintenance and inspections of electronic equipment are necessary to identify and address any potential issues that could lead to static damage.

Tip: Create a checklist for employees to follow when handling electronics to ensure all necessary precautions are taken.

By following these best practices, organizations can significantly reduce the risk of static damage and protect their valuable electronic equipment.

Conclusion

Static electricity poses a significant threat to our electronic devices, causing irreversible damage and costly consequences. Understanding the nature of static electricity and its potential to harm electronics is the first step in protecting our valuable equipment. Grounding plays a crucial role in dissipating static charges and ensuring the safety of our devices. By implementing proper grounding methods and using anti-static mats and wristbands, we can minimize the risk of static damage. Additionally, educating employees about static electricity, implementing ESD control measures, and conducting regular maintenance and inspections are essential in preventing static-related incidents. Real-life case studies serve as reminders of the devastating impact static damage can have on our electronics. By learning from these incidents and adopting best practices, we can create a static-safe environment and safeguard our electronics from static electricity.

Frequently Asked Questions

What is static electricity?

Static electricity is the imbalance of electric charges on the surface of a material. It occurs when two objects with different electrical charges come into contact or are rubbed together, causing electrons to transfer and create an electric charge.

How does static electricity damage electronics?

Static electricity can damage electronics by creating a sudden surge of electric current that exceeds the device’s capacity. This surge can cause components to overheat, short circuit, or become permanently damaged, leading to malfunction or failure.

What are common sources of static electricity?

Common sources of static electricity include friction between materials, such as walking on a carpet or wearing certain clothing fabrics. Other sources include dry environments, synthetic materials, and static-generating equipment.

What is grounding?

Grounding is the process of connecting an electrical device or system to the Earth or to a reference point that has a zero electric potential. It provides a path for electric charges to safely discharge, preventing the buildup of static electricity.

Why is grounding important for electronics?

Grounding is important for electronics because it helps to dissipate static charges and provides a safe path for excess current to flow, protecting the devices from damage. It also helps to reduce electromagnetic interference and improve the overall performance and reliability of electronic systems.

What are the types of grounding methods?

The types of grounding methods include electrical grounding, which involves connecting the device to the Earth using a grounding wire, and functional grounding, which involves connecting different parts of a system to a common reference point to maintain a consistent voltage level.